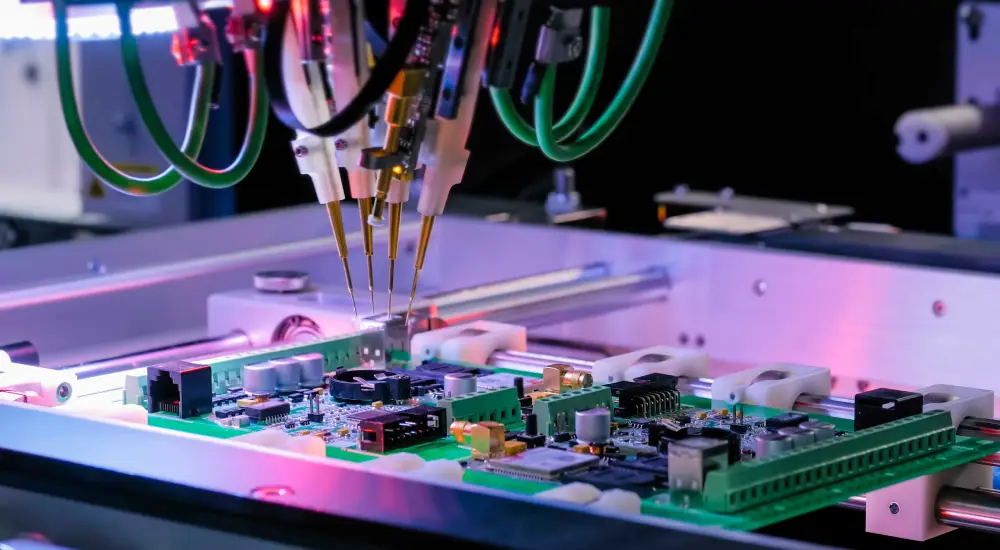

Automated Test & Stand Design

Automated test systems provided by AMTech range from simple setups with a laptop and a DAQ module to more complex stand-alone controllers. These systems typically involve a combination of off-the-shelf and custom hardware, all integrated and wired into a test stand.

Portable and Mobile Test Stands

Portable or mobile test stands are designed for in-the-field research and development and servicing of multiple laboratories or manufacturing lines. Features include:

- Access to front panels of hardware and subcomponents for manual configuration of non-automated settings

- Quick disconnects, cable harnesses, and easy access to probes for efficient setup and tear-down

- Expandable or modular rack-mount and card-base systems for future needs

- Ergonomic considerations such as keyboard and display placement, along with the number of monitors

- Safety features including proper E-stop placement and keeping dangerous elements away from users

AMTech's Test Stands - Hardware Meets Software

AMTech’s automated test stands are typically programmed with LabVIEW, although they work with other languages and platforms. They design custom PC Boards, flexible card modules, and custom backplanes for special signal routing when necessary. Hardware platforms from various vendors are integrated, using existing driver sets when possible or building custom interfaces to automate the complete system. These vendors include:

- National Instruments

- Agilent/Keysight

- Keithley

- Pickering Interfaces

- KEYENCE

- Omega

- Tekronix

- Yokogawa

- Measurement Computing/IOTECH

- Fluke

- UEIdaq

- Brooks

- Princeton Applied Research

Depending on project needs, AMTech can assist through the entire life cycle of automated test station development and deployment, or target specific critical areas to support internal engineering efforts, including:

- Defining test requirements and capabilities

- Test stand architecture, design, and layout

- Test automation software development

- Design of custom PCBs for test interface signal routing

- Integration and assembly of DAQ systems and instruments

- Validation and verification

- Design and solution documentation

- Training and support